Our Technologies & Markets

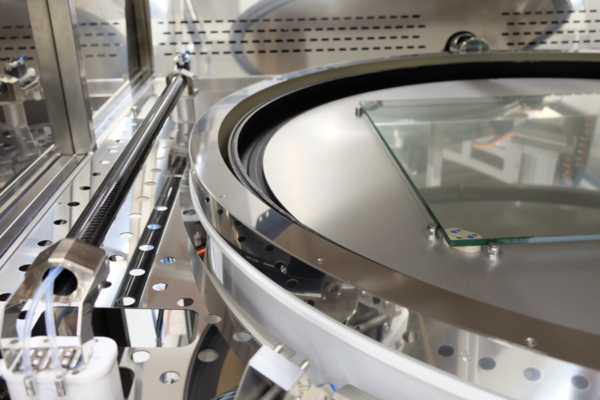

We provide customers with a competitive edge through the delivery of cost-effective lithography solutions. We offer Nanoimprint Lithography- , Resist Processing- and Wet Processing tools as well as Foundry Services.

Obducat’s technologies are highly innovative and are tailored for successful use in industrial High Volume Manufacturing as well as within R&D work. The technology portfolio represents unique and industry leading capabilities in the areas of Nanoimprint Lithography, Resist Processing and Wet Processing. Several of our key technologies are covered by our patent portfolio encompassing close to 200 granted patents.

Obducat’s micro-and nano lithography solutions enable our customers to increase the performance of their products as well as develop new functionalities in existing products. Obducat’s key markets are found within industries such as LEDs and displays, Optics and Photonics, Bio and Medical devices as well as MEMS and Sensors.