Our Technologies

Our Technologies

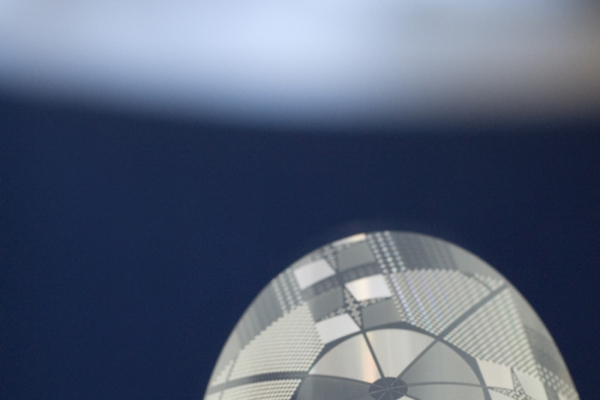

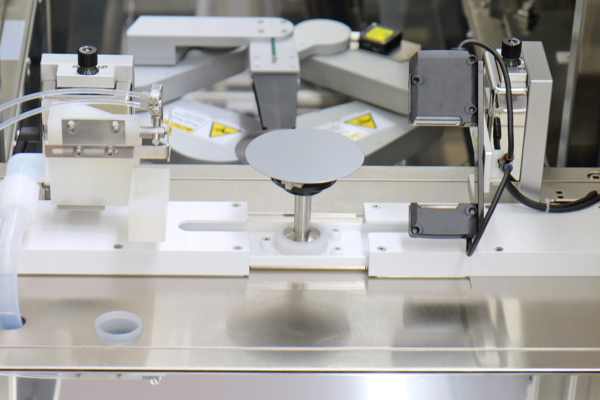

NanoImprint Lithograhy (NIL)

Obducat’s strong technology portfolio and expertise in process know-how makes us the most capable supplier in the Nanoimprint Lithography (NIL) market today. The Obducat NIL-system are easy-to-operate NIL tools suitable for industrial High Volume Manufacturing, product development as well as R&D within academia.

Illustrations, photos and specifications on this Website are not legally binding. Pictures could show standard equipment plus options.

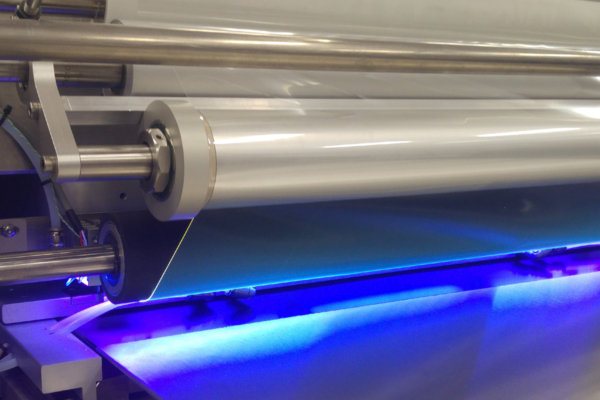

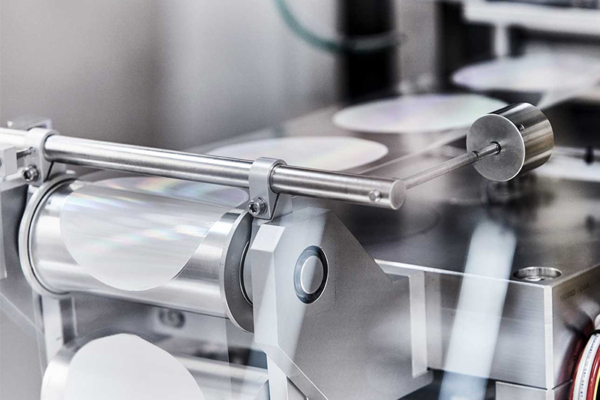

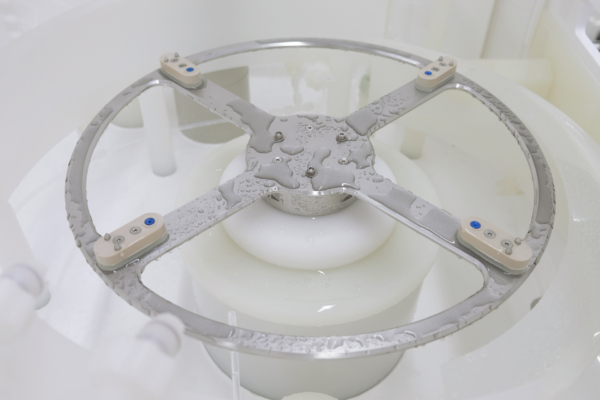

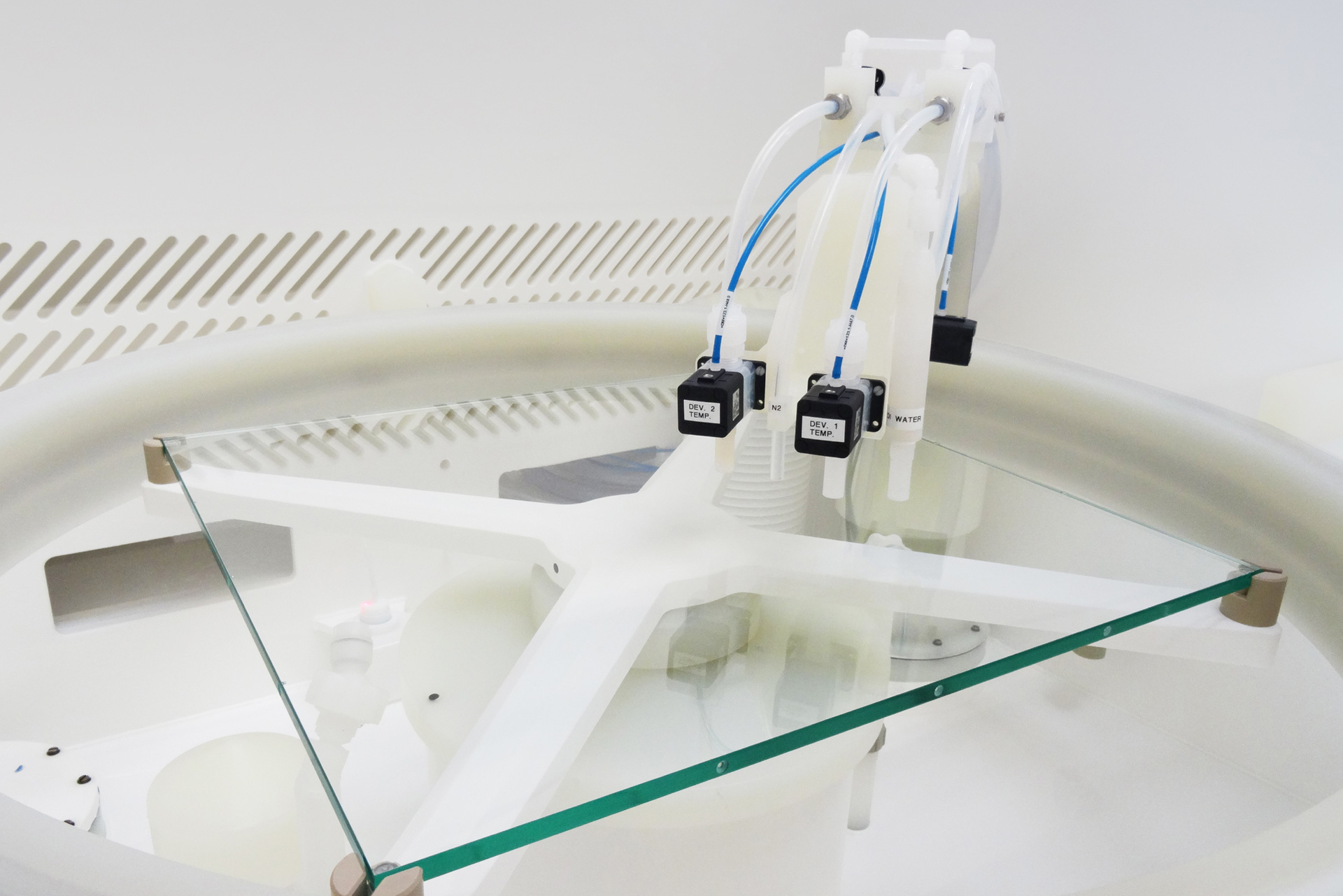

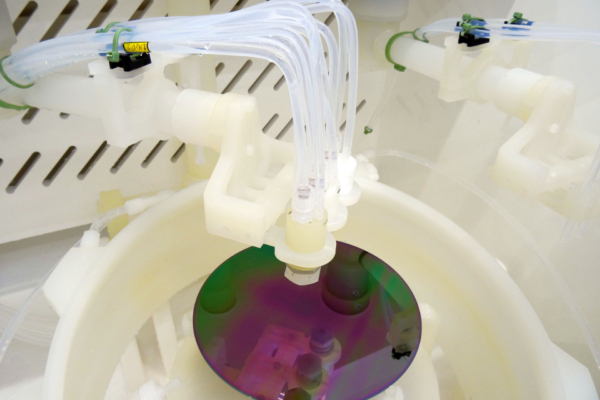

Resist Processing

Resist processing technology is widely used within semiconductor manufacturing. By implementing technologies such as the revolutionary RCCT™, the high performing EBR or our multiple chuck solutions we offer highly competitive and cutting-edge resist processing systems to the marketplace. Obducat have developed several highly advanced technologies that our tools can be configured with to meet the individual customer requirements.

Illustrations, photos and specifications on this Website are not legally binding. Pictures could show standard equipment plus options.

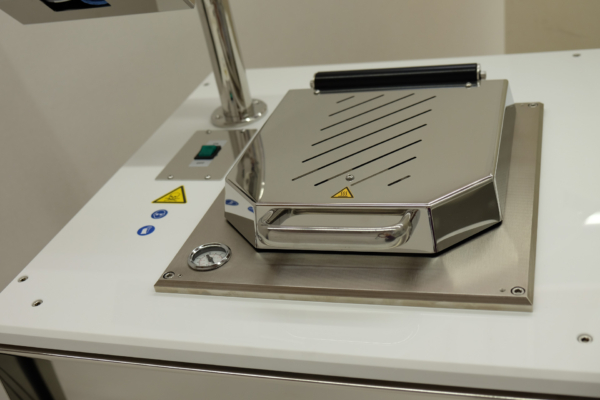

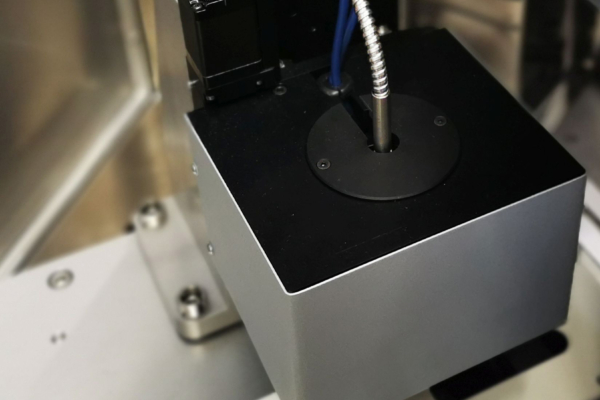

Flood exposure – photoresist image reversal

The flood exposure module is used for photoresist image reversal often used for Lift-Off Processes.

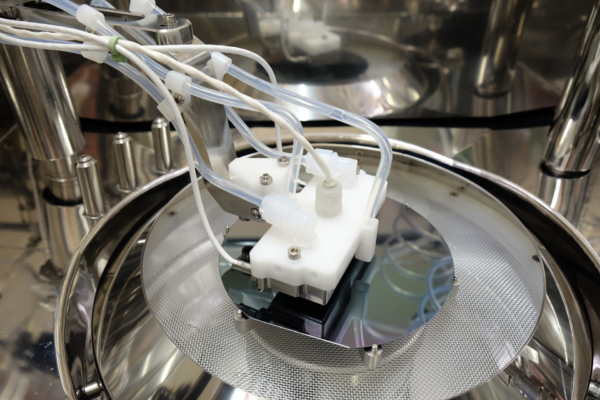

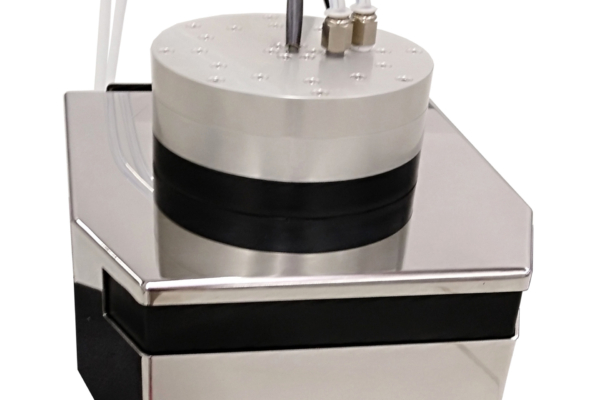

Wet Processing

Various type of wet processes such as Etch, Clean, Lift-Off and Stripping are widely used within semiconductor manufacturing. With a unique competence and versatile tool solutions we offer highly competitive and cutting-edge wet processing tools to the market. Obducat have developed several highly advanced technologies that our tools can be configured with to meet the individual customer requirements.

Illustrations, photos and specifications on this Website are not legally binding. Pictures could show standard equipment plus options.