Products & Foundry Services

NxQ product portfolio

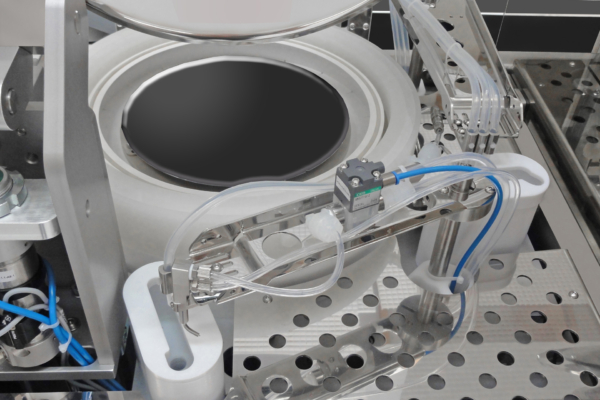

Neutronix is a widely recognized supplier of mask aligner and photolithography systems. The company is a full-service manufacturer, providing customers with one single source for training, equipment maintenance and parts replacement.

NxQ mask aligners are designed for use in both R&D and production settings. With a range of price points and functionality to meet any need, mask aligner systems from NxQ will provide a high performance, cost-optimized solution for any need.